|

Blue Coating Strip Absorber

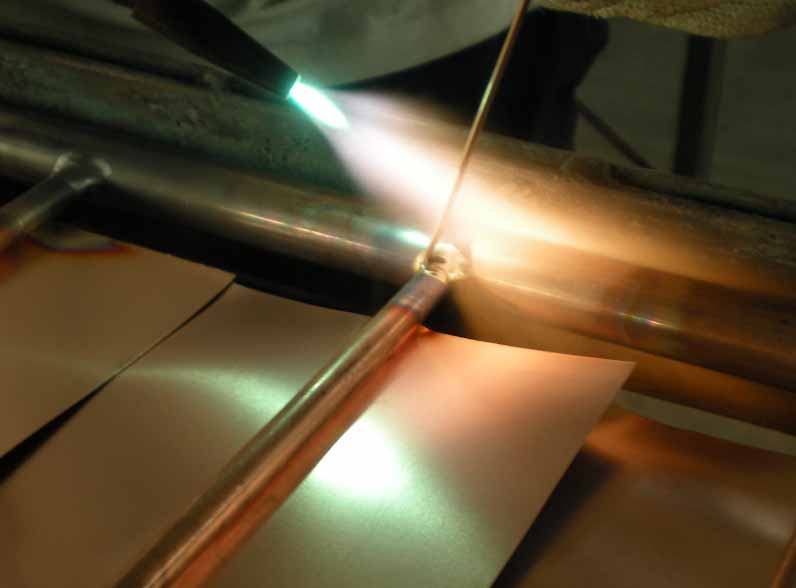

During the ultrasonic welding process, the bonding takes place in a solid state, without any melting of the parts being joined. This is accomplished by overlapping the weld metals and rubbing them against each other using low-pressure, high-frequency mechanical oscillation. Within a fraction of a second, a permanent, solid and metallurgically pure connection with outstanding physical properties is created.

The ultrasonic welding process offers the user a number of economical, technological and not least importantly ecological advantages which form the foundation for the worldwide success of this method: → high-quality metallic bond

Ultrasonically welded absorber fins. The connection between the copper pipe and the sheet copper was made by roll seam welding.

Good melting properties. Silver enhances flow. Enhances capillary flow, improves corrosion resistance of less-noble alloys, worsens corrosion resistance of gold and palladium.

Technical Parameter:

MODEL NO.: Solar Absorber with blue coating We supply High-uality unglazed solar absorber with High-efficiency sputtering blue coating for customers. |

Ultrasonic welding allows the welding of materials with different melting temperatures, such as aluminum and copper for example.

Ultrasonic welding allows the welding of materials with different melting temperatures, such as aluminum and copper for example.